Silico Manganese – High-Carbon Ferroalloy

Original price was: $900.00.$850.00Current price is: $850.00.

Silico Manganese is a ferroalloy composed of manganese, silicon, and iron, primarily used as a deoxidizer and alloying agent in steel production. Cavin Resource supplies high-grade SiMn in bulk quantities for the metallurgy, foundry, and steelmaking industries with global shipping and full documentation.

Silico Manganese (SiMn) is a crucial ferroalloy in the steel industry, typically containing 60–70% manganese, 10–20% silicon, and a balance of iron. It plays a vital role as a deoxidizer and alloying element in steel production, improving steel's hardness, strength, and corrosion resistance. It also minimizes oxygen content during the smelting process, ensuring cleaner and higher-quality end products.

Cavin Resource offers bulk-grade silico manganese produced via submerged arc furnaces, available in various specifications to meet construction, infrastructure, automotive, and tool steel requirements. Our SiMn meets ISO, ASTM, and other international metallurgical standards. With customized packaging, COA, MSDS, and global logistics, we’re ready to meet wholesale buyers' needs across continents.

⚙️ Production Method

Submerged Arc Furnace Process (SAF)

A mix of manganese ore, coke, quartz, and fluxes is charged into a submerged arc furnace.

Through reduction at high temperatures, silicon and manganese reduce from their oxides and combine to form silico manganese.

The molten alloy is tapped and cooled into lumps, which are then crushed and sized for industrial use.

🏭 Applications & Industry Use Cases

🏗️ Steel Manufacturing

Used in the production of carbon steel, stainless steel, and high-strength low-alloy steels.

Improves hardness, tensile strength, and abrasion resistance.

🔩 Casting and Foundry

Enhances fluidity and prevents oxidation during cast iron and steel casting.

🚧 Construction and Automotive

Ideal for reinforcing steel used in buildings, bridges, and automobile parts requiring high performance.

✅ Benefits of Silico Manganese

🔧 Acts as a powerful deoxidizer during steelmaking

🛡️ Improves toughness, wear resistance, and ductility in steel

🔬 Enhances metallurgical quality by reducing sulfur and oxygen

🌍 Cost-effective and widely available in global steel markets

⚙️ Critical in producing durable and high-performance steel alloys

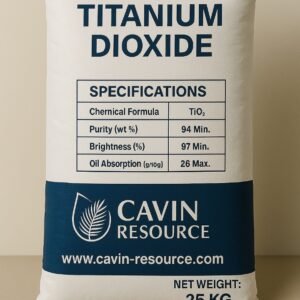

📦 Packaging Options

25 kg woven polypropylene bags

1-ton jumbo bags

Bulk orders available in containerized shipments

COA and MSDS included with every shipment

❓ Frequently Asked Questions (FAQs)

1. What is the typical composition of silico manganese?

Answer: Our SiMn alloy typically contains 65-70% manganese, 15-18% silicon, and the balance iron, with low carbon and sulfur levels depending on the grade.

2. Why is silico manganese used in steelmaking?

Answer: It acts as a deoxidizer and alloying agent, helping eliminate oxygen and sulfur, improving the mechanical properties of the steel.

3. Can I request a custom grade for specific steel applications?

Answer: Yes. Cavin Resource provides customized SiMn grades to meet specific industrial or national standards for different steel grades.

4. Is your silico manganese suitable for export?

Answer: Absolutely. All our products come with full export documentation, and we support global shipping, including port-to-port logistics and custom clearance support.

📚 Credible Sources for SEO & Research

Additional information

| Product Name | Silico Manganese |

|---|---|

| CAS Number | 37291-31-7 |

| HS Code | 7202300000 |

| Molecular Composition | Mn: 60–70%, Si: 10–20%, Fe: Balance |

| Appearance | Metallic grey lumps |

| Purity | High-grade alloy |

| Packaging | 25 kg / 1-ton jumbo bags / bulk |

| Compliance | ISO, ASTM, RoHS |

| Application | Steelmaking, casting, automotive |

| Shelf Life | Stable under dry storage conditions |

| Production Method | Submerged Arc Furnace |

| Country of Origin | Available upon request |

Reviews

There are no reviews yet.